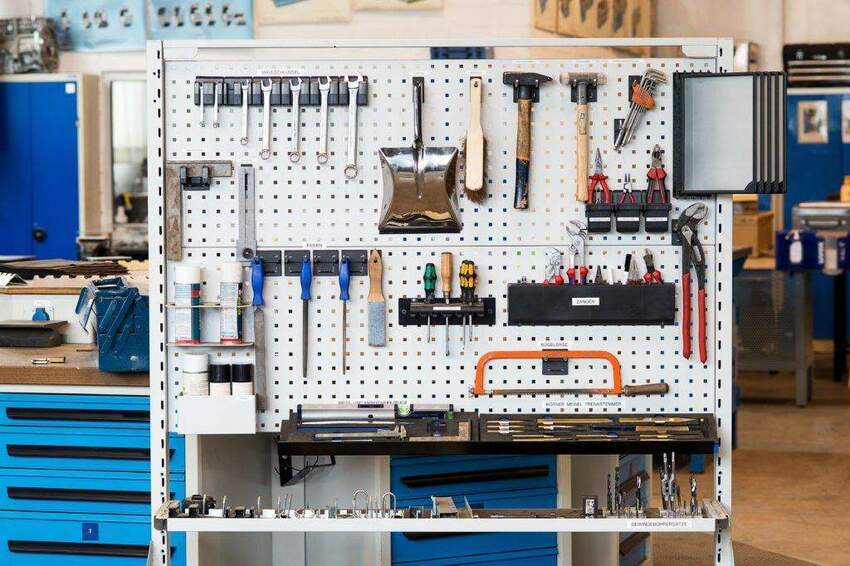

The 5S’s are lean concepts derived from the Japanese words: seiri (sort), seiton (set in order), seiso (shine or purity), seiketsu (standardize), and shitsuke (sustain) (Hirano, 1996).

Witaj w Artelis

Internetowym Mieście Twórczej Wymiany Energii, budowania wizerunku w sieci, praktycznej wiedzy i naturalnej aktywności.

Wymień się energią – opublikuj swój artykuł z wiedzą lub inną treść. Pozwól innym się poznać, przekaż im część siebie i też i skorzystaj z wiedzy innych osób – czytaj i pobieraj artykuły, komentuj, dziel się nimi w sieci. Wszystko co robimy jest wymianą energii.

Chcąc skorzystać z Artelis

Aby bezpłatnie publikować artykuły podpisz je swoim imieniem i nazwiskiem. W stopce autorskiej umieść link do swojej strony, bloga, profilu, który chcesz promować i wyślij do nas – taka publikacja jest bezpłatna.

Jeśli jednak potrzebujesz również w treści artykułu umieścić elementy reklamy

Tak czy owak, dołącz już teraz do naszego Miasta Twórczej Wymiany Energii! Działajmy razem w tym zmieniającym się świecie. A jeśli chcesz wiedzieć więcej o nas, to zobacz „O Artelis” znajdziesz tam więcej informacji o naszym Serwisie.