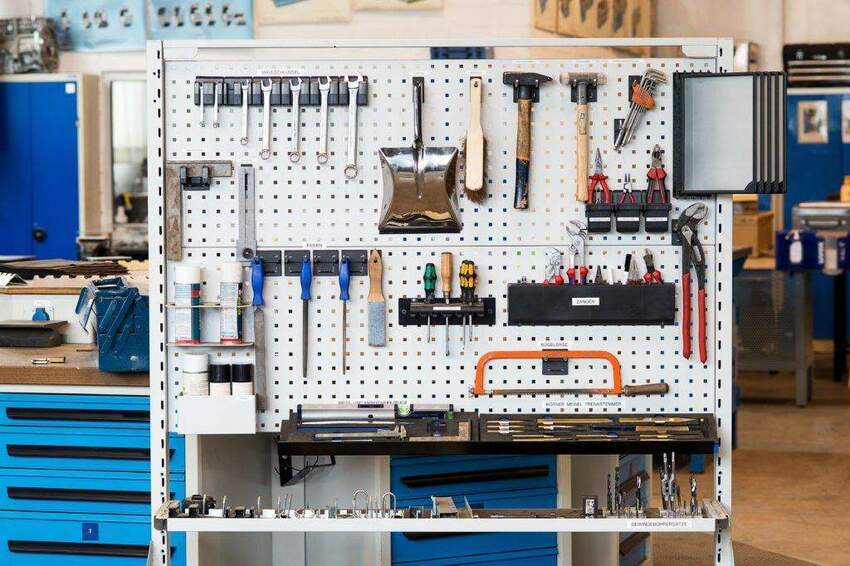

Effective lean workplaces use 5S (Sort, Scrub, Set in order, Standardize and Sustain) and Visual Systems. With a place for everything and everything in place, out of control situations are clearly visible. Included are guidelines, features and examples of 5S and visual systems - readily transferable to your situation.

Abstract: Visual Controls are central to any successful Lean transformation. A all-designed Visual System supports other Lean tools with applications such as reinforcing standard work practices, displaying performance trends, providing visual maintenance reminders, highlighting tool locations, scheduling production, and controlling inventory levels.

One of the better-known methods of implementing Visual Controls is by following the 5S program (Sort, Scrub, Set in order, Standardize and Sustain). This presentation describes a framework and guidelines for implementing a system of Visual Controls. It will demonstrate application of 5S to transform workplaces and measure results.

Many examples of Visual Controls are included using the following target areas: - Practices in the Workplace - Personnel - Policies & Coordination - Procedures – Methods - Production Control - Process Control & Quality Improvement - Productive Maintenance - Protection & Safety - Performance Management

Many photographs from a variety of companies illustrate these methods of making the workplace selfexplaining and self-maintaining. Before and after photos and metrics for 5S applications are included. This is a practical presentation, providing many transferable tools.

Guidelines, techniques and examples showcase the value of Visual Controls and some implementation tips. Participants should discover several ideas they can readily apply to their workplace.

Participants Will Learn: - Definitions and guidelines to support 5S program implementation - Practical tips and examples to help understand and install Visual Controls - Applications 5S with before and after photos with results achieved - How 5S and Visual Controls support other Lean Tools - Several practical ideas to apply to their situation.